3D printing in custom fashion manufacturing: a game changer

3D printing in custom fashion manufacturing revolutionizes the industry by enabling sustainable production, enhancing customization, and integrating smart technology, while also addressing challenges such as technical integration and market acceptance.

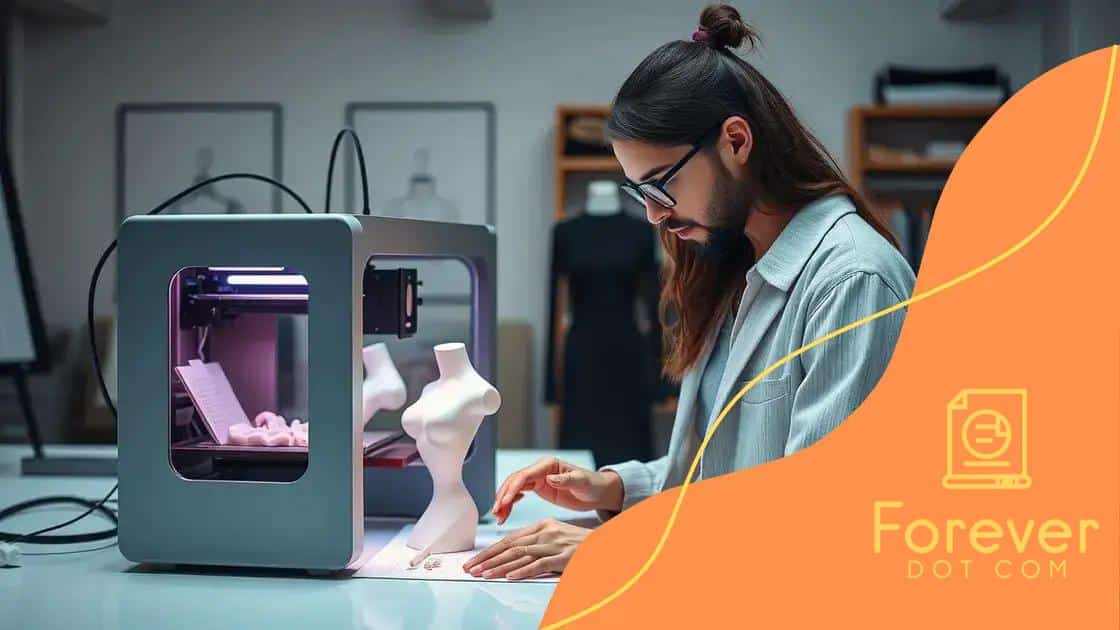

3D printing in custom fashion manufacturing is transforming the way we think about clothing design. Imagine a world where styles are not only unique but also tailored precisely to your needs. Curious how this technology could change your wardrobe?

Understanding 3D printing technology

Understanding 3D printing technology is essential for grasping how it revolutionizes many industries, including fashion. This innovative method uses digital designs to create 3D objects layer by layer, allowing for incredible precision and customization.

How 3D Printing Works

The process begins with a digital model that can be designed using various software. Once the design is ready, the 3D printer follows the model to fabricate the object. Different materials can be used, such as plastic, metal, or even fabrics.

There are several types of 3D printers, each catering to specific needs:

- FDM (Fused Deposition Modeling) – common for prototyping with plastic.

- SLA (Stereolithography) – utilizes resin for detailed and smooth finishes.

- SLS (Selective Laser Sintering) – works with powdered materials, suitable for complex shapes.

With these technologies, designers can create intricate patterns and structures that were once impossible. The flexibility that 3D printing offers in custom fashion manufacturing is unmatched.

Applications in the Fashion Industry

3D printing opens up new avenues for fashion. Brands can create unique pieces tailored to individual customers. With 3D technology, it’s easy to design clothing that fits perfectly or to make unique accessories that stand out.

This technology not only streamlines production but also reduces waste. By printing only what is needed, designers minimize excess materials that often end up in landfills.

The integration of 3D printing technology in fashion is paving the way for sustainable practices and creative freedom in the design process.

The role of customization in fashion

The role of customization in fashion is becoming increasingly important in today’s market. Customers are no longer satisfied with generic designs. Instead, they seek unique pieces that reflect their personal style.

Why Customization Matters

When brands offer customization, they give customers the chance to express themselves. This leads to greater satisfaction and brand loyalty. Customized fashion caters to individual preferences, and that’s a significant shift in how we view apparel.

Here are some reasons why customization is essential:

- Increased customer engagement.

- Higher perceived value in products.

- Ability to create one-of-a-kind items.

With 3D printing technology, customization is easier than ever. Designers can quickly adapt their creations to suit specific requirements. This means not only can styles be tailored, but fit can also be optimized for various body types.

Examples of Customization

Brands today are embracing personalization. For instance, some companies allow customers to choose colors, materials, and even designs. This level of engagement makes shopping more interactive and enjoyable.

Many athletes and fitness enthusiasts appreciate customized sportswear. With 3D printing, they can have shoes designed for their specific foot shape. This innovation enhances comfort and performance significantly.

Moreover, customization helps address environmental issues. By producing exactly what consumers want, brands reduce waste and improve sustainability. This alignment with eco-conscious values resonates well with modern consumers.

Benefits of using 3D printing in garments

The benefits of using 3D printing in garments are reshaping the fashion industry. This technology brings several advantages that enhance both design and production processes.

Innovation in Design

First, 3D printing allows for incredible creativity. Designers can experiment with complex shapes and patterns that traditional methods cannot achieve. This freedom leads to unique creations that stand out in the market.

Some specific benefits include:

- Rapid prototyping and adjustments.

- Lower production costs for intricate designs.

- Ability to create lightweight and durable pieces.

Moreover, the speed of production increases significantly. With 3D printing, items can go from concept to reality in a fraction of the time. This agility allows brands to respond quickly to trends and consumer demands.

Cost Efficiency

Using 3D printing also makes manufacturing more cost-effective. Since materials are only used when needed, waste is reduced. This approach is especially appealing in today’s eco-conscious market.

Additionally, fewer resources are required for production. There is less need for inventory storage, and shipping costs can be minimized since items can be printed on-site.

By adopting 3D technology, brands can create on demand, eliminating overproduction and allowing for easier inventory management. This leads to a more sustainable fashion model.

Personalization Opportunities

Another significant advantage is the ability to customize garments. Customers can personalize fit, style, and materials, leading to a more engaging shopping experience.

This level of customization not only satisfies consumers but also fosters brand loyalty. When customers feel that a brand reflects their personal style, they are more likely to return. Thus, 3D printing opens doors to enhanced relationships between brands and their clientele.

Challenges faced in integrative manufacturing

Challenges faced in integrative manufacturing are significant as the industry evolves. While advances like 3D printing create opportunities, they also introduce new obstacles that must be addressed.

Technical Difficulties

One of the primary challenges is overcoming technical limitations. 3D printers need to operate flawlessly to produce high-quality garments. Issues with material compatibility or printer calibration can lead to poor results.

Common technical challenges include:

- Inconsistent printing precision.

- Material restrictions limiting design options.

- Software complexity requiring specialized knowledge.

These technical hurdles can cause delays in production and increase costs. To mitigate these issues, manufacturers must invest in training and better equipment.

Integration with Existing Processes

Another challenge is integrating new technologies into traditional manufacturing processes. Companies often struggle to adapt their workflows to include 3D printing. This transition can lead to disruptions and may require significant changes in how teams operate.

Furthermore, aligning teams across different departments is crucial. Efficient communication and collaboration are necessary to ensure a smooth transition to more modern manufacturing methods.

Another aspect to consider is the need for skilled workers. As new technologies emerge, companies must find and train employees who can handle advanced machinery and software. This can lead to increased training costs and potential talent shortages.

Market Acceptance

Finally, market acceptance poses a significant barrier. While many consumers appreciate the benefits of customization, some remain skeptical about the quality and durability of 3D printed garments. Overcoming this perception requires education and effective marketing strategies.

Brands need to build trust by showcasing successful 3D printed products, emphasizing their quality and sustainability. Additionally, feedback from early adopters can help shape future offerings and improve customer understanding.

Future trends in 3D printed fashion

Future trends in 3D printed fashion are set to redefine the industry. As technology advances, we can expect exciting developments that reshape how we create and consume clothing.

Growth of Sustainable Practices

One significant trend is the emphasis on sustainability. With the fashion industry facing criticism for its environmental impact, 3D printing offers a path to more eco-friendly production. By reducing waste and allowing for on-demand manufacturing, this technology supports sustainable practices. Consumers are increasingly seeking brands that prioritize the planet, which pushes industries toward greener solutions.

The shift towards sustainability may include:

- Use of biodegradable materials.

- Reduction of overproduction and waste.

- Local production to decrease transportation emissions.

With these practices, brands can appeal to environmentally conscious consumers, leading to a more sustainable future in fashion.

Enhanced Customization

Another trend is enhanced customization. As 3D printing technology becomes more accessible, consumers are likely to demand even more personalized products. This trend allows individuals to tailor garments to their specific preferences. Expect to see features like customizable fits, colors, and designs that reflect a person’s unique style. As a result, brands will cater to diverse fashion needs more effectively.

The future may also bring:

- Integration of augmented reality for virtual try-ons.

- Collaborations with artists for unique designs.

- Apps that enable easy customization from smartphones.

These innovations will make shopping more interactive and fun.

Integration of Smart Technology

The fashion industry is also expected to integrate smart technology into 3D printed garments. Imagine wearable technology that monitors health or changes color based on the environment. This intersection of fashion and function will create truly unique pieces. Consumers will not only wear fashionable items but also benefit from functional features.

Such advancements could include:

- Clothing that adapts to temperature.

- Garments with built-in fitness tracking.

- Smart textiles that respond to body movements.

This merging of technology and fashion will lead to innovative creations that enhance the wearer’s experience.

FAQ – Frequently Asked Questions about 3D Printed Fashion

What are the main benefits of 3D printing in fashion?

3D printing offers innovative design flexibility, cost efficiency, and the ability to create personalized garments, making it a game changer for the industry.

How does 3D printing reduce waste in the fashion industry?

3D printing allows for on-demand production, where items are created as needed, minimizing overproduction and excess inventory.

What challenges do brands face when adopting 3D printing technology?

Brands often encounter technical difficulties, integration issues with current processes, and market acceptance hurdles when implementing 3D printing.

What future trends can we expect in 3D printed fashion?

Future trends include a greater focus on sustainability, enhanced customization options, and the integration of smart technology into clothing.